What is SafeBatt?

Whilst battery fires are rare, they can occur under various conditions of mechanical, thermal or electrical stress or abuse. As the use of LiBs expands into automotive, stationary storage, aerospace and other sectors, there is a need to decrease the risk associated with battery usage to enable the design and optimisation of safety systems. This project will improve the fundamental understanding of the root causes of cell failure and the mechanisms of failure propagation. Working closely with industry partners, a multi-scale approach is being taken, from the material to the cell and module scale.

The project is also developing an improved understanding of processes occurring during real world failure, including the environmental consequences of LiB fires, which will inform the further development of fire sensing and protection systems for battery energy storage systems and help inform first responders.

SafeBatt is composed of five parallel work streams:

WP1: Degradation / safety intersection

SafeBatt encompasses the science of safety from the microscopic, materials level to the cell and module length scales, and time scales spanning the degradation of materials (over 100s cycles) down to the nucleation and propagation of thermal runaway with characteristically sub-second events.

SafeBatt employs state-of-the-art measurement and characterisation techniques to understand the causes of cell failure, the interplay between cell degradation and safety, as well as the safety implications of fast charging and operation under extreme conditions.

WP2: Instrumented, high-speed, scientific failure

There is a critical need to understand and mitigate the risks of thermal runaway, whereby events during abnormal cell operation can trigger a cascade of exothermic processes, ultimately leading to catastrophic cell failure.

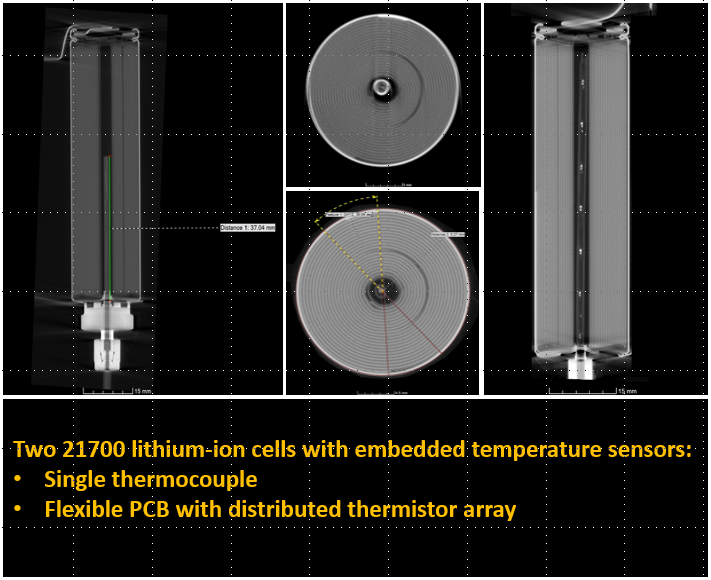

We use high resolution, high speed visualisation and instrumentation techniques to understand why cells fail as they do and how different failure modes affect cell-cell thermal runaway propagation. Integrating sensors directly into the cell allows quantification of key internal states of the battery during failure as well as providing data for model parametrisation.

Testing large scale packs is hazardous, slow and expensive, thus does not support agile development of propagation mitigation strategies. SafeBatt is developing a minimum cell cluster & enclosure concept for cells, which will allow us to investigate barrier materials for mitigation of thermal propagation.

WP3: Pack/EV/LIBESS testing

and real world response

This Work Package focuses on improving our understanding of the dynamic processes occurring during real-world failure. Carrying out large scale testing (e.g., modules and packs) helps us understand how applications at pack level change the safety requirements at cell level.

SafeBatt is also investigating different fire extinguishing technologies and looking at the toxicity of fumes and run-off from Li-ion battery fires.

The output from this Work Package helps provide best practices and understanding to stake holders such as government, standards and regulatory bodies, industry, OEMs and first responders.

WP4: Modelling to inform the science of safety

SafeBatt has expanded its reaction network modelling to modelling thermal runaway in a cell, including the flame and ejecta, as well as propagation.

A model is being developed simulating Li-ion cell thermal runaway from first principles to predict off-gas species and the reaction pathway to thermal runaway.

Extending this beyond cell level, we want to understand and predict the consequences of battery failure, e.g., the large heat output of flaming cells, by modelling three aspects of battery failure: (1) what occurs at cell failure and the potentially resulting fire, (2) initiation of thermal runaway and (3) how thermal runaway propagates to neighbouring cells.

WP5: dissemination and policy influence

In our ongoing collaboration with a net of international battery and fire professionals the SafeBatt team regularly engages with academia, industry, policy makers, general public and first responders on safety related battery topics. Our engagement with automotive, aerospace and energy storage sectors guides the trajectory of this work in response to contemporary industry need, ensuring the project delivers commercially relevant science and practical safety solutions.

Working closely with industry, government and policy makers, we aim to influence standards and our international work training and advising first responders such as Fire & Rescue Services is invaluable in keeping them safe.